In 2008, Aulick provided support on one of the most important dam foundation remediation projects in the history of the U.S. Located on the Cumberland River in south central KY, Wolf Creek Dam provides hydropower, flood control, water supply, and water quality benefits for the Cumberland River system and surrounding region.

Created by the dam is Lake Cumberland, a popular and important attraction in Kentucky both economically and recreationally. In 2007, the U.S. Army Corp of Engineers (USACE) placed Wolf Creek Dam under high risk for failure designation and launched a major foundation remediation project to bring the dam to full operation.

The remediation project was awarded in 2008 to TREVIICOS-Soletanche, Joint Venture, for the construction of a 980,000 sq ft concrete barrier. Specialized equipment designed and built for this project was used by TREVIICOS to excavate through the embankment and into the rock foundation.

While these methods used by TREVIICOS were both ground breaking and industry leading (Directional Drilling and Reverse Circulation Drilling), the drilling produced hundreds of thousands of gallons per day (GPD) of treatable wastewater from drilling and ground/source water.

In order for this major rehabilitation project to be a success, TREVIICOS was required by law to treat all wastewater produced to an acceptable level for release back into the Cumberland River.

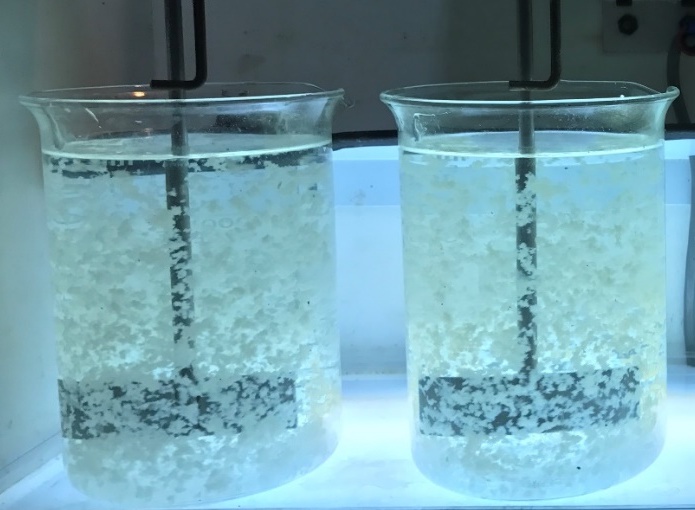

Through strategic jar testing services and Chemical Feed System design, Aulick successfully identified our SC-408 chemistry (for water release into the environment) and AulFlocc polymeric chemistries (to recycle useable water) to treat and release process water back into the environment and reuse.

For additional information on the Wolf Creek Dam remediation project, visit TREVIICOS here.

2014 – Much like the improvements needed at Wolf Creek Dam, so too were improvements needed at Tennessee’s Boone Dam located in Sullivan and Washington Counties. In October 2014, the Tennessee Valley Authority (TVA) discovered a sinkhole near the base of the embankment at Boone Dam where water and sediment were found seeping from the riverbank below.

The risks associated with the seepage, as identified by the TVA, were:

- Flooding

- Property damage

- Economic losses

- Environmental impacts

- Loss of critical infrastructure

- Potential loss of life

The TVA identified a composite seepage barrier as the preferred option to remediate the problems at Boone Dam. A composite seepage barrier creates a positive cutoff from the reservoir and is made from non-erodible material. Therefore, this solution has a low probability of a seepage connection within the reservoir recurring.

2019 – Similar to the project at Wolf Creek Dam, the construction performed at Boone Dam to make the necessary improvements required drilling into the earth. The drilling produced wastewater that needed treated before it could be released into the environment.

Process water at Boone Dam was full of clay and dirt that washed off during ground operations and rain events. Discharging the untreated water into the South Fork Holston River could compromise aquatic life and water quality for the numerous drinking water treatment facilities down stream.

In this application, the solution was again SC-408. During jar testing sessions, it was determined that the SC-408 would be the most effective at coagulating the impurities found in the water for release into the South Fork Holston River.

For more detailed information on the Boone Dam remediation project, visit the TVA here.