Industrial Pretreatment Coordinators must understand the importance of aiding municipal wastewater treatment personnel prior to discharge to the WWTP.

Not only can inadequately-treated industrial wastewater disturb the biological balance of the WWTP, but it can also result in hefty fines from municipalities to industrial manufacturers if contaminants are over predetermined limits.

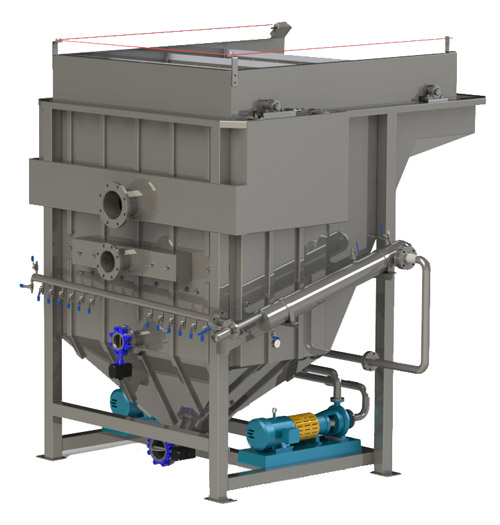

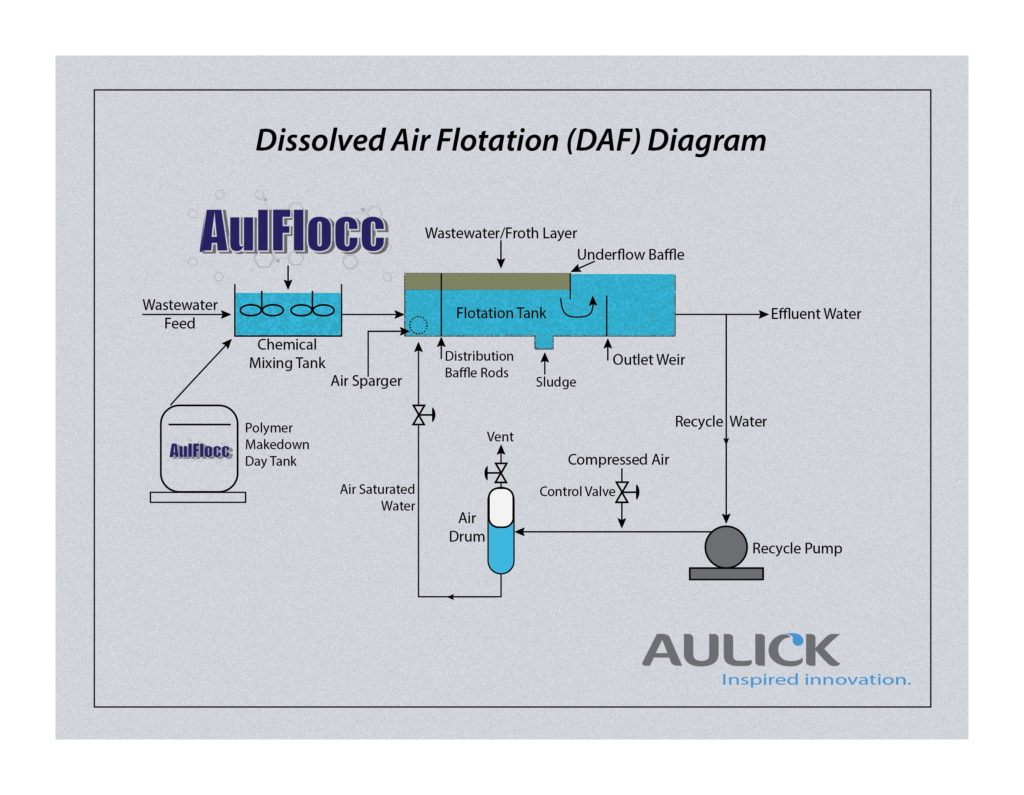

It’s widely known that Dissolved Air Flotation (DAF) Systems aid pretreatment personnel in removing unwanted materials in the waste stream such as grease, oil, and suspended solids. DAF Systems are effective in a number of industrial applications including but not limited to:

- poultry and meat processing

- rendering

- paper industry

- metal plating

- bakeries

Municipal Applications:

- phosphorous and algae removal

- biological solids clarification

- sludge thickening

*In most applications, however, the correct coagulant or flocculant must be chosen by the operator to ensure optimal DAF System performance in their pretreatment or wastewater treatment applications.

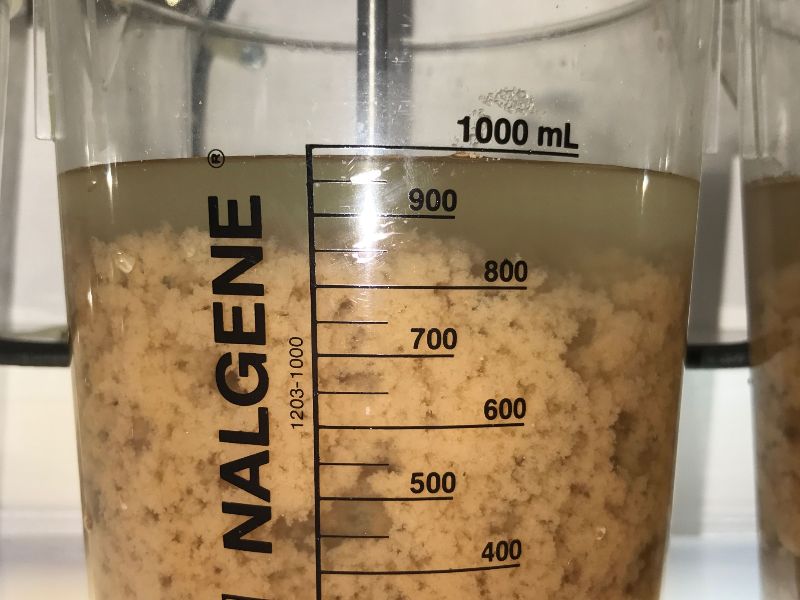

In an industrial wastewater setting, Aulick tested multiple AulFlocc polymers to determine the correct solution.

2mL of Aulick’s AulFlocc C-6652 was mixed into 400mL of wastewater (0.5% solution). Aulick’s AulFlocc C-6652 at 4mL performed best and provided the customer with the best value when cost and performance were both considered.

Aulick offers complete jar-testing services to industrial, municipal, and pretreatment personnel to ensure optimal performance for DAF Systems.

Jar-testing services include:

- trial of multiple AulFlocc line of polymers

- technical support

- monitoring and reporting

- AulFlocc – cationic and anionic granular and emulsion polymers

- complete jar-testing services performed to evaluate precise polymer for individual applications

- used in a broad range of solid-liquid separation in both municipal and industrial wastewater applications

- used in belt press applications

The proper method of doing this is using a polymer blending make-down system. Neat polymer is fed from a bulk polymer tote to a peristaltic pump mounted on the PBS. Pressurized water is supplied to the PBS. The neat polymer is injected into a water stream and enters a blending chamber to be unwound. The neat polymer feed rate and water feed rate are adjusted to produce a 0.5%-1% make-down solution at the discharge of the PBS. This polymer solution is then plumbed to a polymer day tank.