Superior Collection System Odor Control

Prevent Hydrogen Sulfide Odor And Protect Against Corrosion

Ready to learn more? Reach us here

Regional Leader In The Fight Against Hydrogen Sulfide Odor And Corrosion

Eliminate Your Residential Odor Complaints And Protect City Infrastructure

Hydrogen sulfide in the sewer collection system is the leading cause of community odor complaints utility personnel face each year. It’s also the culprit behind the damage caused by corrosion to municipal infrastructure that can be difficult to manage and expensive for municipalities. Aulick’s custom hydrogen sulfide prevention plans are based on field testing and data and are quickly implemented to resolve the issues caused by hydrogen sulfide by preventing its formation.

Custom Odor Control Solutions

Accurate Chemical Application

Field Testing In Your Collection System

Each utility collection system is unique. That's why Aulick is dedicated to field testing to determine hydrogen sulfide origin point as well as on-going testing after chemical application. At Aulick, we understand variables.

Custom Chemical Feed Systems

Dial in chemical feed rates while remotely monitoring chemical inventory with an Aulick odor control system. Our Systems personnel can also provide preventive maintenance on your chemical feed system.

Reliable and Professional Chemical Delivery

24-48 hour bulk delivery capabilities with Aulick owned and operated fleet allows us to deliver chemical on time and as expected.

Solid-Liquid Separation In Municipal And Industrial Wastewater Treatment

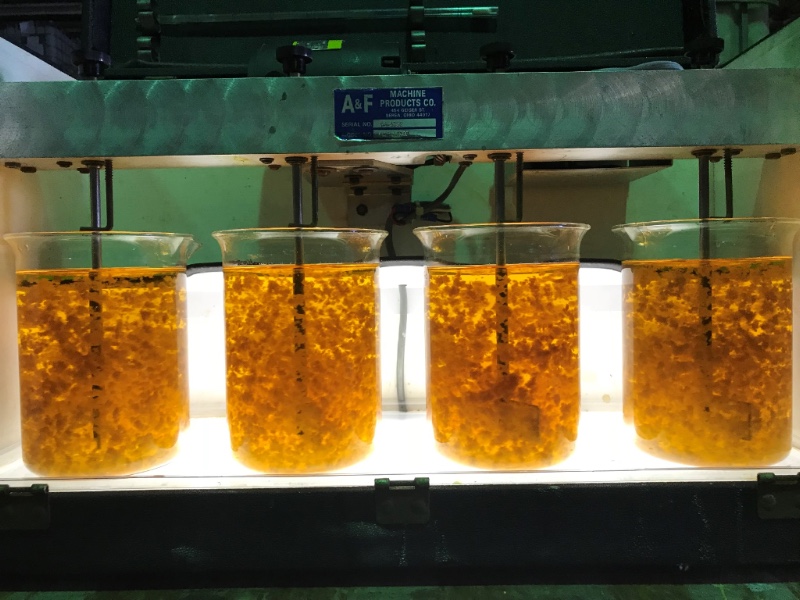

Cationic/Anionic Granular and emulsion polymers

Aulick Chemical Solutions utilizes decades of coagulant and polymeric chemistry experience and detailed jar-testing services to find the right chemistry for your specific application.

Aulick's Premium AulFlocc Line

The AulFlocc line works especially well with aerobic digested sludge, belt filter and screw presses, metals removal, clarifiers and dissolved air flotation (DAF) systems.

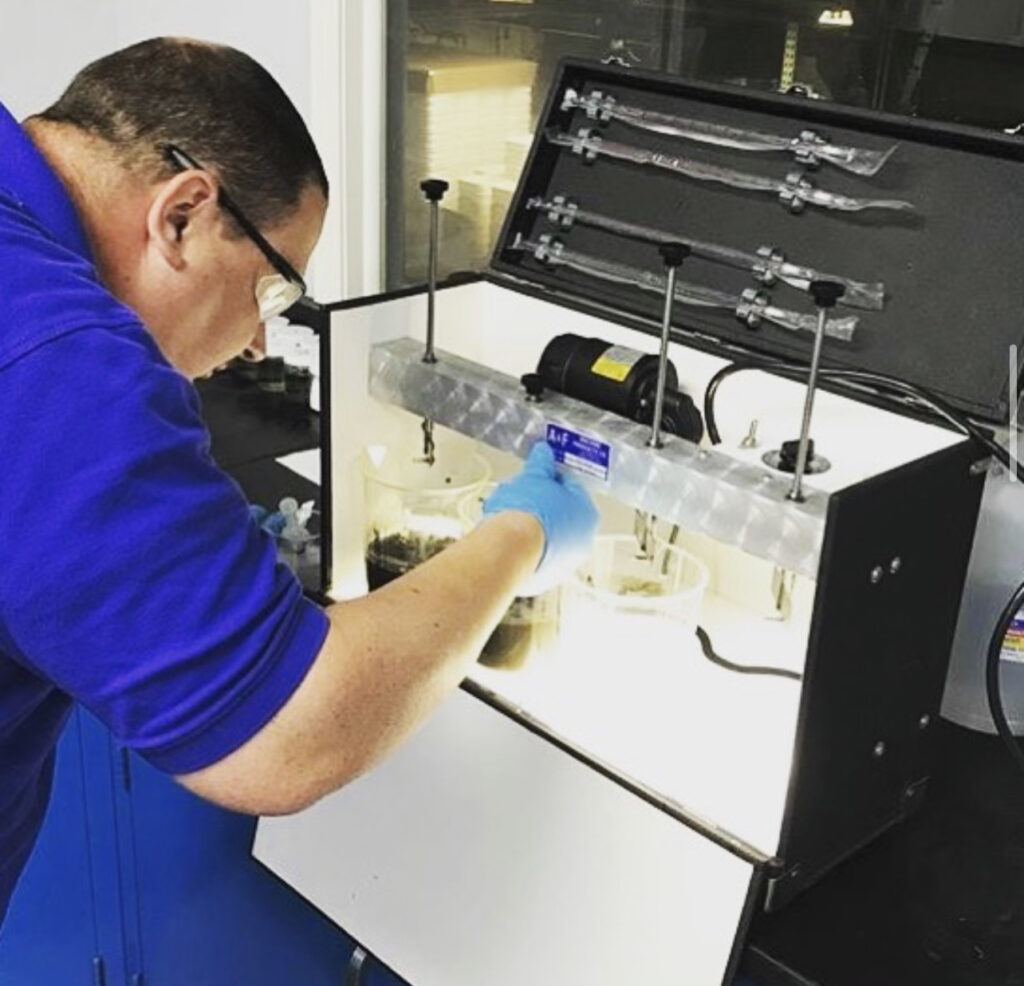

Not A 'One-Size-Fits-All' Science

Aulick Technical Consultants come on site to determine the right chemistry for your application by performing strategic jar-testing services.

Variety Of Treatment Strategies

Our best practices include a variety of treatment strategies that include over 75 blends of our premium AulFlocc line of polymers.

Disinfection By-Product Solutions

Major compliance issue facing water systems today

Aulick utilizes in-depth and custom strategies to lower disinfection by-products for water systems in the Southeast U.S. and beyond.

Regulated Disinfection By-Products

Disinfection By-Products from chlorination are the major compliance issue facing water systems in the Southeastern U.S. today. Aulick has assisted multiple systems in Tennessee and Kentucky to successfully lower their disinfection by-products utilizing a variety of strategies.

When it comes to disinfection by-product mitigation, one size does not fit all. Aulick understands that the cause of elevated DBP levels can come from many sources and may require a multi-point strategy.

Whether it’s effectively lowering by-product precursor content or focusing on distribution system health, Aulick technical consultants will thoroughly explore all possible avenues to cost effectively reduce the levels of trihalomethanes (TTHM) and haloacetic acids (HAA) at your utility.

Contact Aulick today to request an onsite evaluation of your water system. We’ll provide you with an in-depth strategy to bring your system into compliance with the disinfection by-product rule.

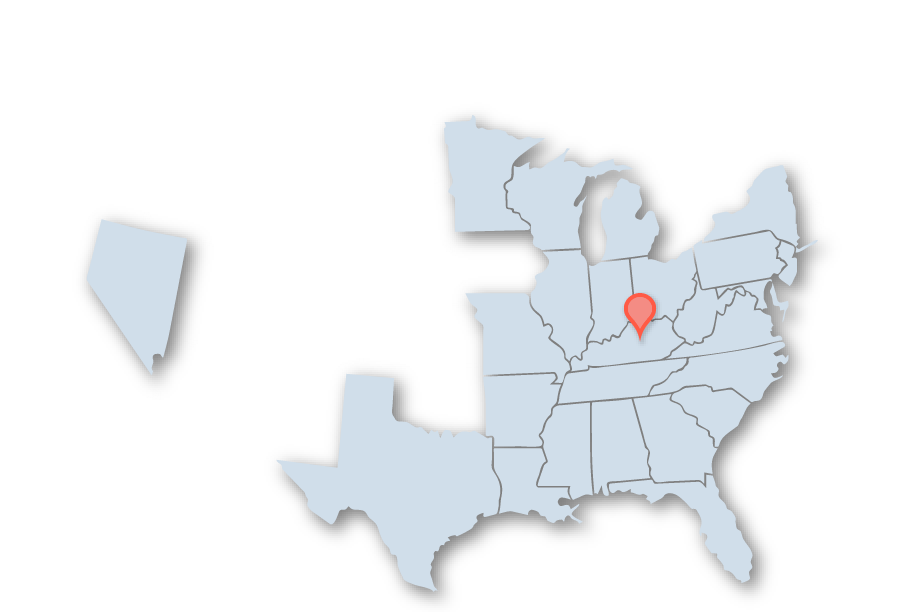

Serving more than 21 states

centrally located. equipped to serve.

We proudly support customers throughout the Southeastern U.S. and beyond. With over 20 years of experience, our capabilities, chemistry, and dedication to great service sets us apart.