Are you in the process of working with a consultant on a new lift station design or build? Aulick – A CITCO Water Company provides professional assistance from project inception to final installation.

Our engineered project services include:

- Chemical Feed System and Feed Rate Recommendation Based On Data Provided

- Complete Scope of Work Provided on System and Chemical

- Flexibility on Engineer Plan Changes or Edits

- Final System AutoCAD Files Provided

- Odor Control System Build, Delivery, and Optional Installation

Additionally, our experience lies in the following when it comes to total turnkey odor control:

- Reliable and Professional Bulk Chemical Delivery by Aulick-Owned Fleet

- Custom-Built Odor Control Chemical Feed Systems, Installation & Preventive Maintenance

- Hydrogen Sulfide Odor Origin Location

- On-Going Hydrogen Sulfide Testing

- Nitra-Nox Chemical Inventory Management Through Aulick Remote Tank Monitoring

- Collection System Mapping to Provide Strategic and Accurate Feed Location

- Performance-Based Monthly Reporting

Understanding Hydrogen Sulfide Odor & Corrosion

Hydrogen sulfide (H2S) is a colorless, toxic, highly flammable gas with a pungent odor similar to that of rotten eggs. Often referred to as “sewer gas”, hydrogen sulfide is a result of the breakdown of organic matter by bacteria, typically in an oxygen deprived environment such as a municipal collection system or wastewater treatment plant.

Controlling this hazardous gas is one of the most challenging problems facing industry and wastewater treatment personnel today. Not only is it a nuisance because of its odor, hydrogen sulfide has the potential, even at low concentration levels, to pose extreme safety hazards for utility personnel, while its corrosive nature is detrimental to plant and collection system equipment.

Concentration levels of hydrogen sulfide in most wastewater collection systems and sludge processing plants are dependent on several factors.

- Agitation – although agitation does not affect the amount of hydrogen sulfide produced, it does play a factor in how much H2S is released. The greater the agitation in a manhole or pump station, the greater amount of H2S that will be released into the air.

- Temperature – sulfate reducing bacteria thrive in the wastewater stream in elevated temperatures up to 98°F. Therefore, the higher the temperature of the wastewater, the greater concentration of sulfate reducing bacterium that produce hydrogen sulfide.

- Microorganism and Sulfate Counts – sulfates serve as an oxygen source for microorganisms in the wastewater stream. When sulfates are consumed, hydrogen sulfide is produced by the microorganisms as a by-product. Thus, the greater the sulfate levels in the wastewater stream, the greater concentration of sulfate reducing bacterium that produce H2S.

- Residence or Retention Time – everyday, miles of sewer lines are installed to accommodate economic and residential expansion. As a result, sewer lines are often oversized to compensate for the rapid growth. These oversized sewer lines lead to greater wastewater residence times. High levels of H2S are produced during these residence times.

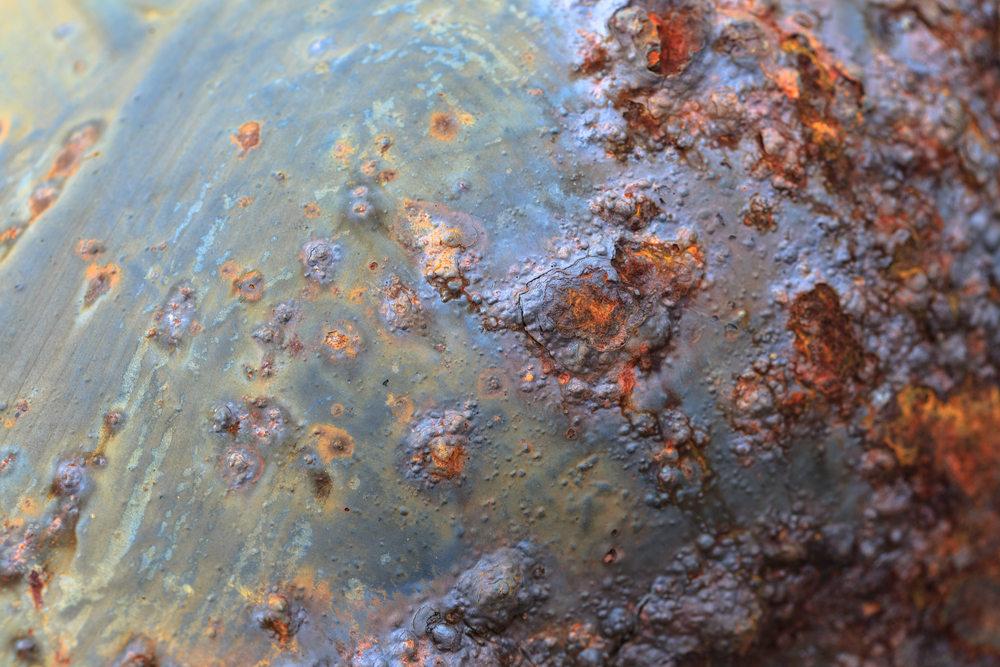

Corrosion To Utility Infrastructure From Untreated Hydrogen Sulfide

Odor Control Systems To Prevent Hydrogen Sulfide

Stainless Steel Chemical Feed System (SS System)

Aulick’s Stainless Steel Chemical Feed System was designed to feed Nitra-Nox to control odor and corrosion in the municipal collection system. This system is customizable based on engineer specifications and features dual pump capabilities to ensure accurate and precise chemical dosage.

Because of its durable design, the Stainless Steel CFS is able to endure harsh wastewater environments to provide reliable odor control for municipalities.

- SCADA Compatible

- Force main injection capabilities

- Remote tank level monitoring capabilities

Motus iDS – Intelligent Dosing System

Designed for precision odor control, Motus iDS operates by reading total organic carbon in the wastewater stream, focusing on retention time, and accurately dosing precise amounts of odor control solution to prevent hydrogen sulfide production.

- Password protected HMI display with tank level and dosing amount display

- Automatic dosing adjusts with flow, rain events, inflow & infiltration, and organic compound changes

- Remote tank level monitoring capabilities

Tank Mount Chemical Feed System (TM System)

The TM System is easily installed and maintained by Aulick personnel for a variety of odor control scenarios. Desired tank size and average daily feed rate only need to be determined in order to complete order and installation.

- No chemical handling by customer

- Professional installation

- Customizable – tank sizes from 100 gallons to 2500 with feed rates from .2GPD to 60GPD.

Fiberglass Chemical Feed System (FG System)

The FG System can withstand higher feed rate and higher pressure applications than the TM System. This single pump system arrives mostly installation ready and is easily maintained by Aulick’s Systems Technicians.

- Corrosion resistant

- Used in force main injection odor control applications

- Part of Aulick’s PM Program

Nitra-Nox Preventive Chemistry Compatible With All Odor Control Systems

Nitra-Nox is a preventive odor control chemistry designed to halt the production of hydrogen sulfide in wastewater. It prevents corrosion to wastewater treatment collection systems and equipment while fighting other odors found in wastewater.

Nitra-Nox is a non-hazardous solution proven to prevent hydrogen sulfide odor and corrosion by serving as an alternative oxygen source to the anaerobic bacteria found in wastewater.

- Non-hazardous

- Prevents corrosion to wastewater collection system and equipment

- Does not affect the pH of wastewater

- Reduces health threats to utility personnel

- Reduces BOD

Aulick – A CITCO Water Company is an industry leader providing custom solutions to clean water. Whether in the public utility sector with water and wastewater treatment systems or in private industry with production and manufacturing facilities, Aulick has the experience to design custom solutions specific to your application.

We’re willing to go the extra mile to eliminate hydrogen sulfide, odor, and corrosion for your Utility or Wastewater application.