Aulick’s Industrial Specialty Chemical Consultant, Jeff Woodrow, was recently tasked with finding a chemical solution for zinc removal for a metal plating company. The company had spikes above the city zinc discharge limits of 3.5 ppm. After samples were gathered, extensive jar testing was performed on-site.

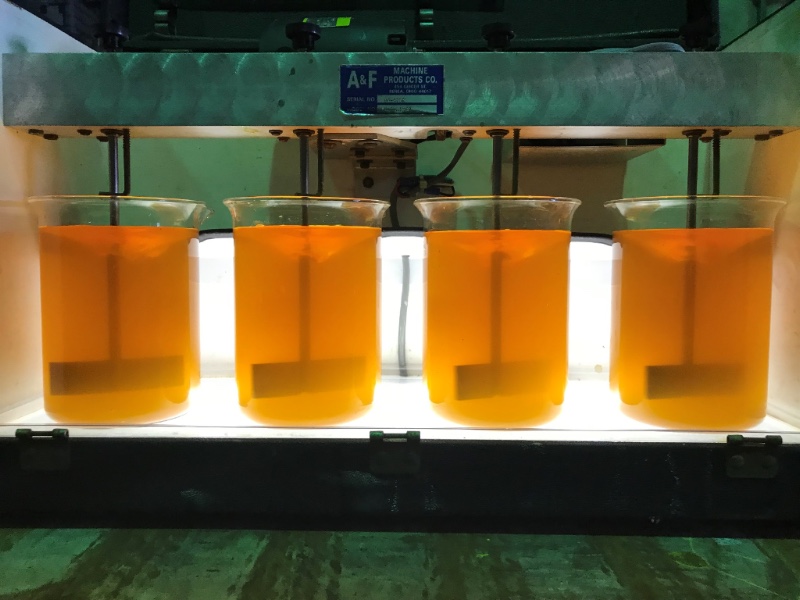

Photo 1 (above) shows the wastewater sample before chemical addition. Sample jars appear 1-4 from left to right.

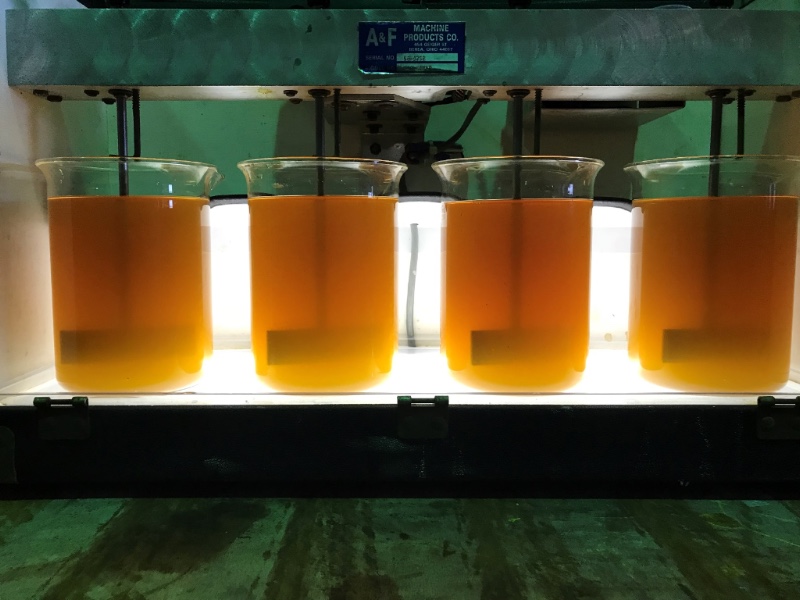

Photo 2 (above) shows the 4 samples after AulClear CFP coagulant was added. A very good pin floc was produced.

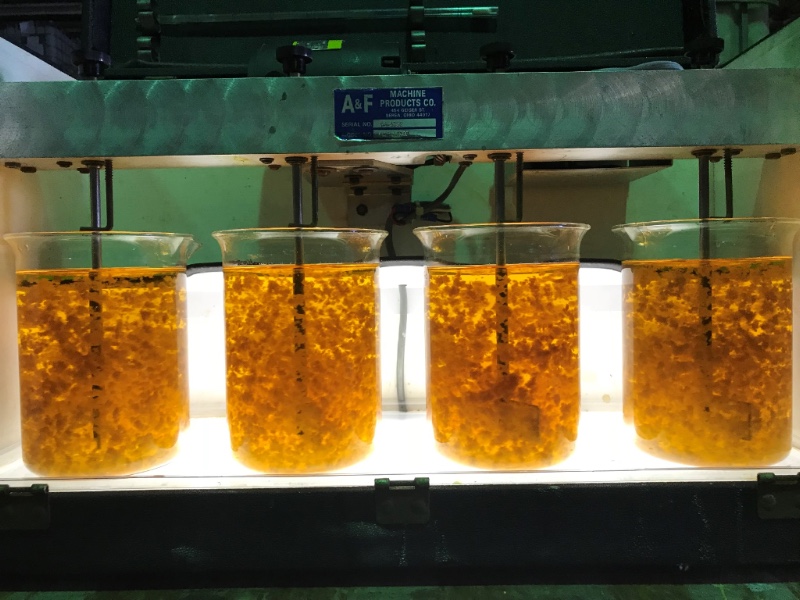

Photo 3 (above) – Our expertise in wastewater treatment results in excellent floc formation. Our flocculant has brought the coagulated pin floc together. This produced a fast reacting, fast settling large floc.

Photo 4 (above) shows the 4 jar samples after settling. Samples were then pulled from each jar and tested for zinc levels by the wastewater treatment operator:

- Jar 1 – 0.64 Zn ppm (no metal precipitant)

- Jar 2 – 0.45 Zn ppm (lowest Zn level with Aulick metal precipitant)

- Jar 3 – 0.65 Zn ppm

- Jar 4 – 0.69 Zn ppm

*Aulick was able to meet discharge limits on all metals and organics. The color left behind in sample photos was from a dye in this particular application’s manufacturing process.

Aulick Chemical Solutions has the knowledge and experience to treat a number of different wastewater treatment applications. Whether it’s removing metals or treating organics, we’re here to help. For additional information on this project or to schedule a site visit, drop us an email below.