Aulick’s Nitra-Nox is a proven preventive hydrogen sulfide solution in the field for over 17 years. But what about locations where hydrogen sulfide already exists?

Answer: Sul-Fight.

Sul-Fight was designed for preventing corrosion and removing odors at these vital locations in the wastewater treatment process (municipal and industrial) where hydrogen sulfide is present:

- Manholes

- Lift Stations

- Sludge Holding Tanks

- Air Scrubbers

- Belt Press Rooms

- Headworks

When Sul-Fight comes in contact with hydrogen sulfide and other sulfurous compounds, the negative charged ion on the sulfur bonds with one of the positive ions on the Sul-Fight.

This reaction produces a non-odorous and non-corrosive sulfonated compound. The reaction is instantaneous and irreversible at ambient temperatures. Unlike metal ions, the Sul-Fight compound is water soluble and does not precipitate out in lift stations, force mains, or gravity sewer lines.

(Pictured Above: high intensity air scrubber in industrial application where Sul-Fight was used to increase the pH. In this specific application, adjusting the pH was more cost effective to the customer due to lower volume of recirculation water to be pH controlled).

Feed Locations

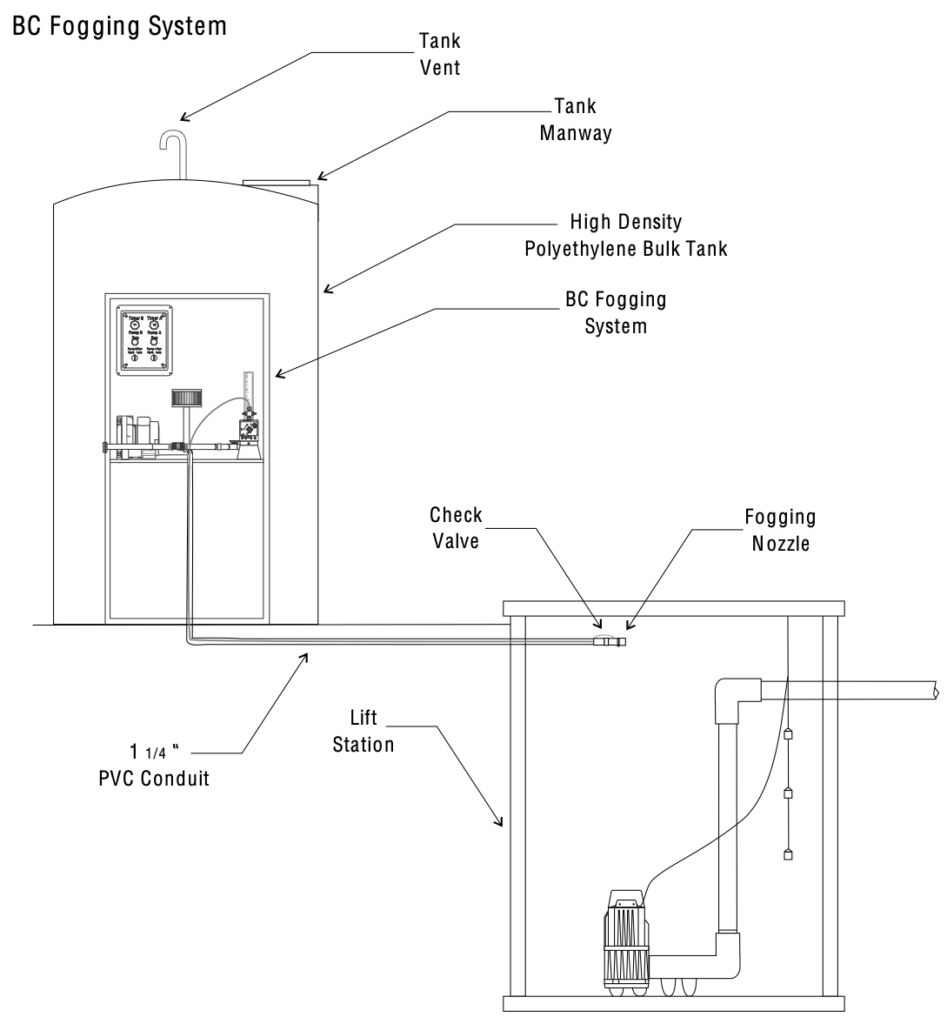

Sul-Fight can be fed into these key feed locations by utilizing Aulick’s B.C. Fogging System, drip fed, or directly injected into the wastewater force main.

- Manholes – B.C. Fogging System

- Lift Stations – B.C. Fogging System

- Sludge Holding Tanks – Direct Inject

- Belt Filter Press – Direct Inject

- Headworks – B.C. Fogging System

- Air Scrubbers – B.C. Fogging System

(Pictured Above: B.C. Fogging System feeding Sul-Fight to Lift Station).

The B.C. Fogging System was designed to fog a variety of Aulick’s chemical solutions into unique applications. This system can start as small as a 42 CFM blower with a single vortex fogging nozzle for smaller application areas.

From that size, Aulick can increase blower size and number of fogging nozzles to meet different coverage areas. Control panel features include:

- Non-metallic

- Corrosion resistant

- Dual 96 increment timers

- Dual auto/on/off switches

- Dual indicator lamps